Fabrication

- Some fabrication done around the shop

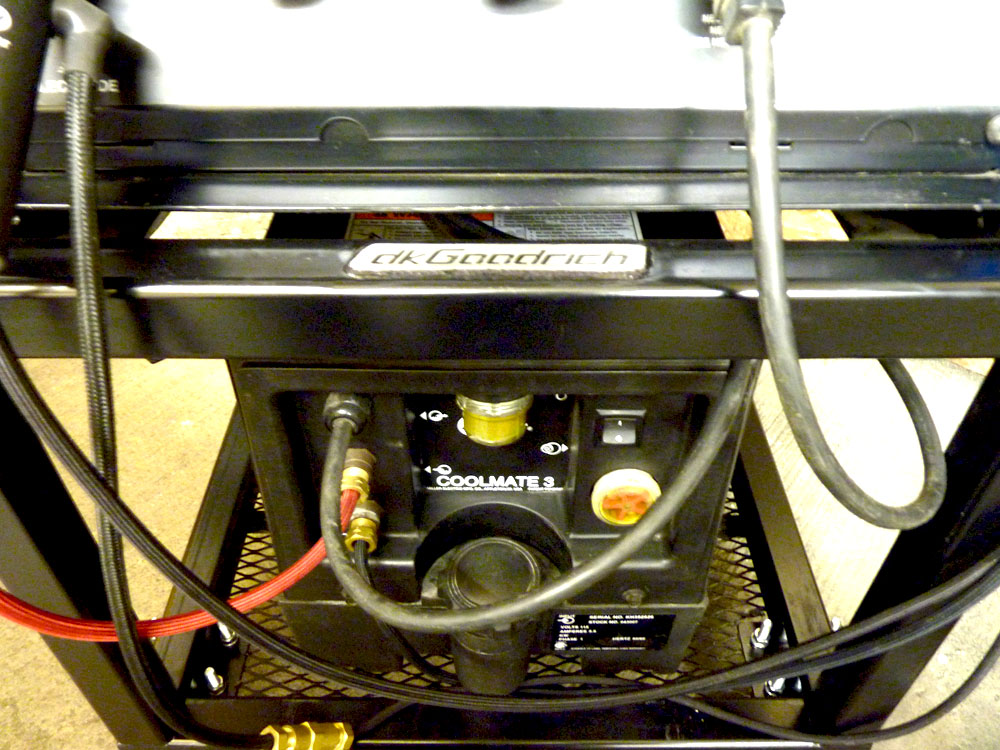

- Coolmate 3 water cooled Miller Syncrowave

- #12, #16, #18 Gas lens on WP20 & WP9 torches

- Pretty much everything is controlled manually via a foot pedal

- I rarely if ever pulse weld

- I mainly TIG weld as a hobby and for my tuning customers

- I don't do much fab work it self, mainly just TIG welding.

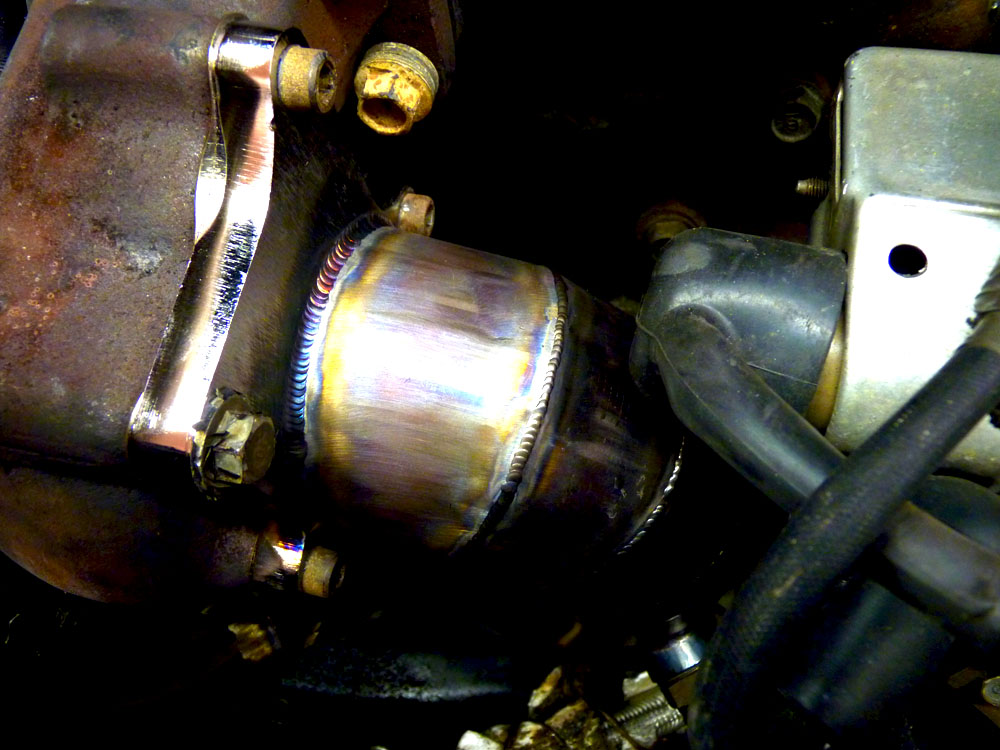

Stainless/Aluminum Turbo Components

38mm EWG Dump tube flange, 1.5" Open dump tube

We typically build our 38mm dumps with a 1.75" tube

Yields a lower 44mmish tone and is more durable

T3 5 bolt flanged 3" 'pie cut' short radius open DP, Baloney/slash cut outlet

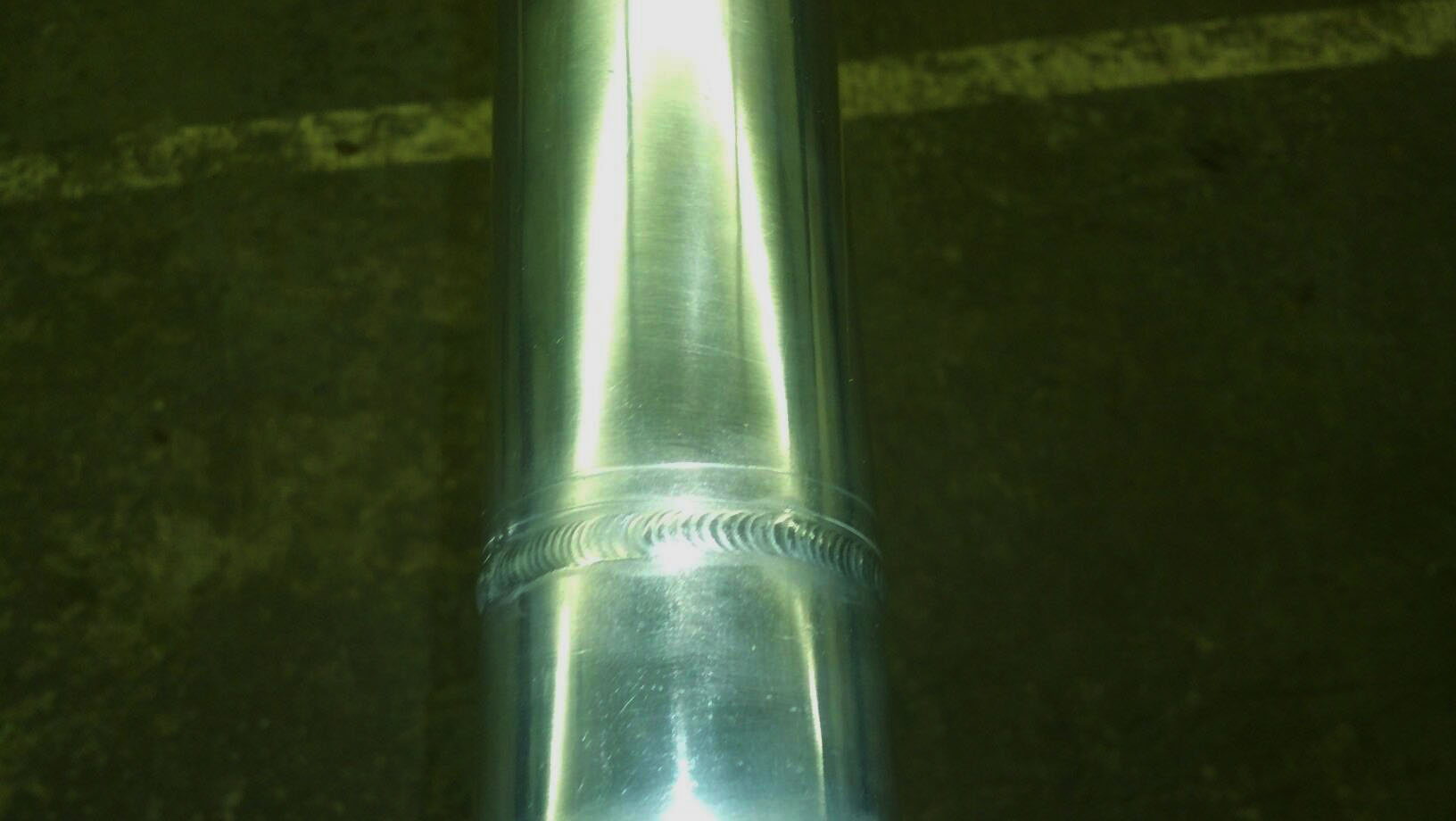

Open T3 flange, SCH10 pipe weld

First thin wall 16 ga. aluminum tube weld

Simple SCH10 SS B series T3 log manifold, 38mm EWG

We only build them out of SCH40 now for added longevity

This one is still on a car today issue free

Has been used on a daily basis since 2009

SCH10 single pass

TIG Welding Bench, Miller Syncrowave, Coolmate 3 Water-cooler, WP20

I've always been a huge fan of Miller products and have ran their welders issue free for more than a decade

I personally like TIG welding with a Miller over most other brands.

I've tested them side by side and have seen first hand, you get what you pay for.

2WD Dyno's Computer Cart, Twin 22" LCD Mount, Stainless Keyboard Top

22" Monitors Mounted, Computer Installed

So far I've used this cart since 2007' and its worked great

I'd like to add swinging wiring booms that will hold sensor cables over the engine bays and off the ground/fenders/window seal

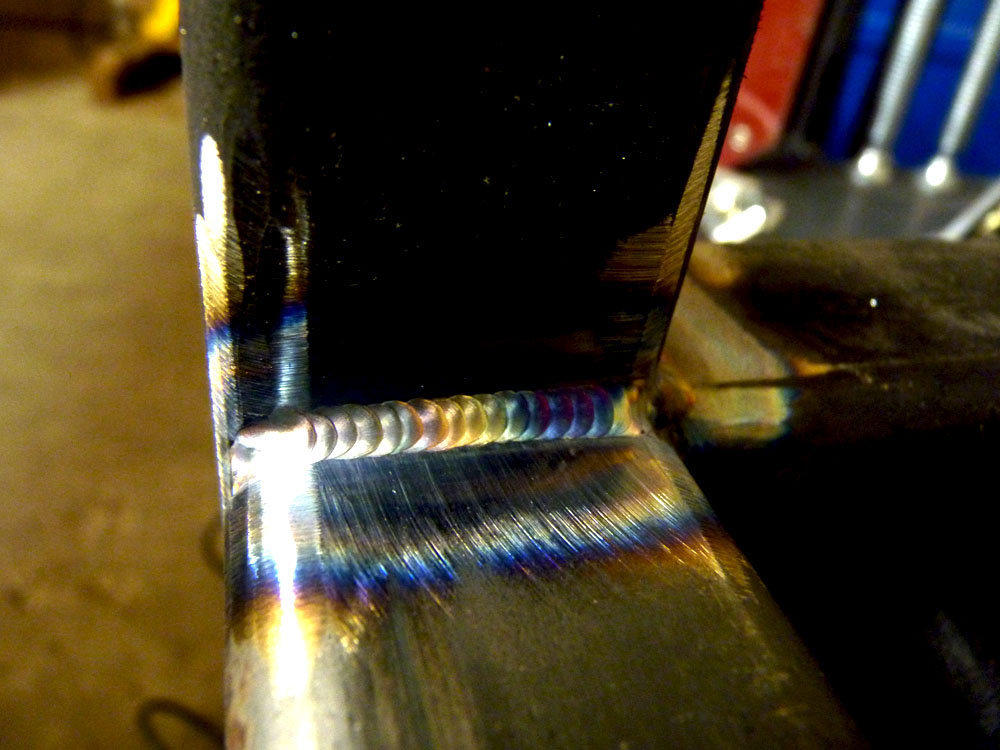

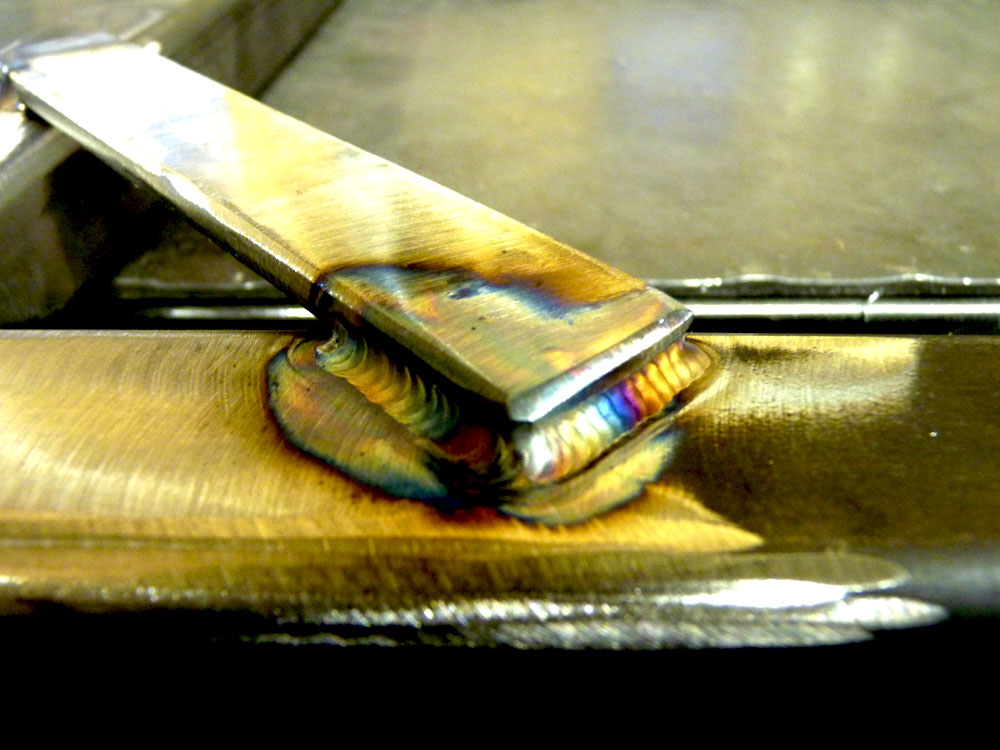

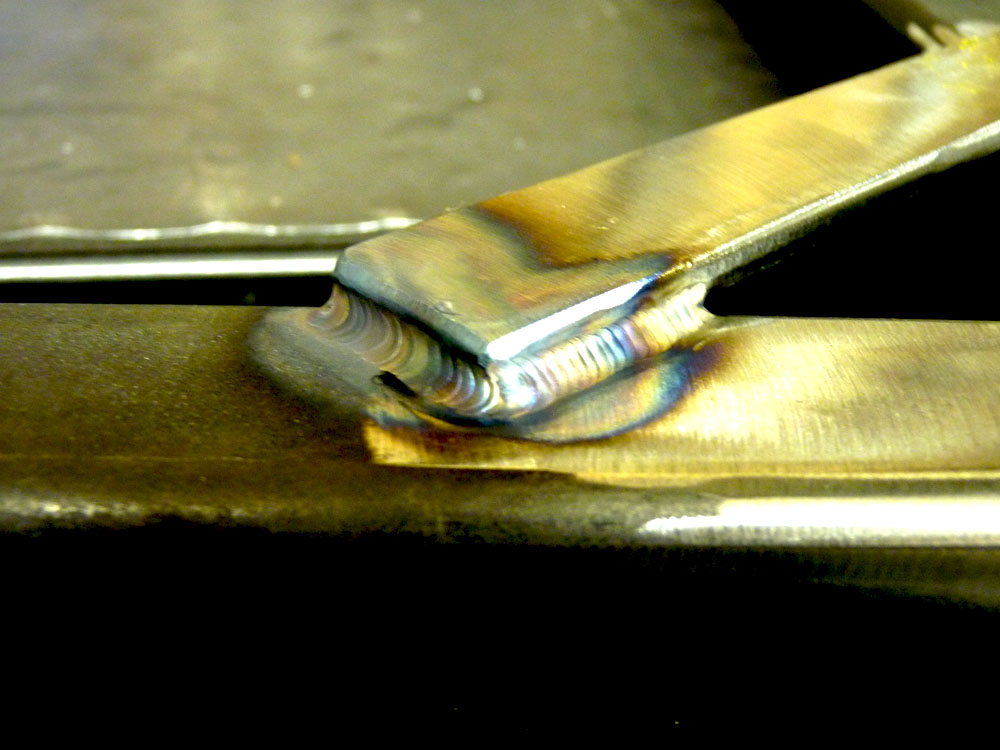

2WD Dyno's Computer Cart Up Close Weld

-

Miller Syncrowave TIG Cart

Single pass on the welding cart

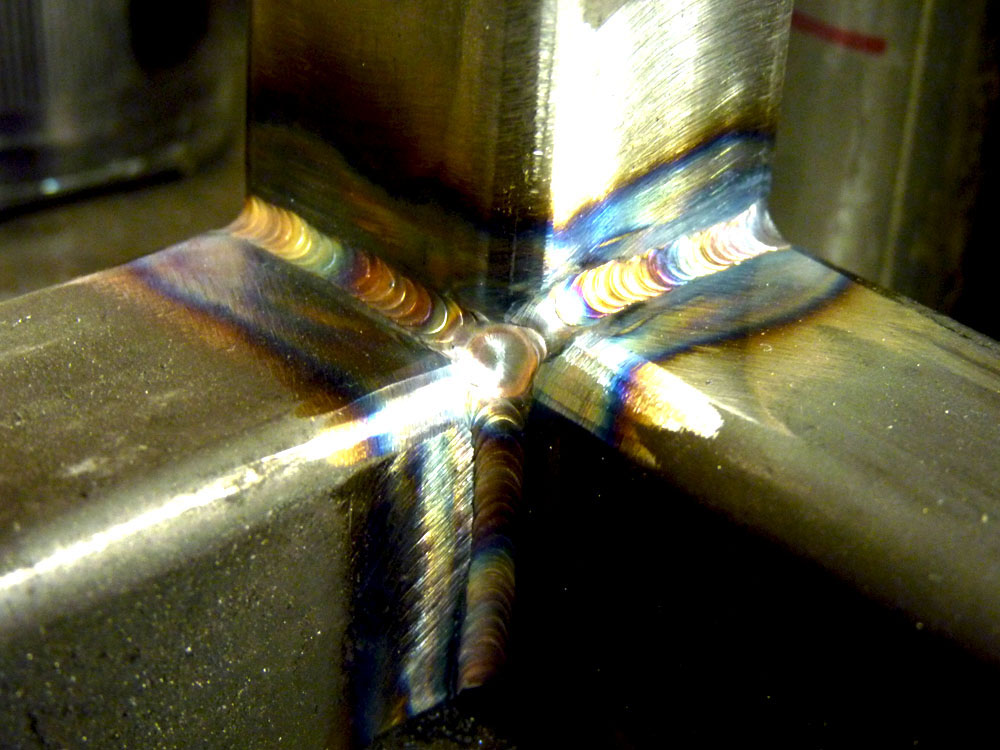

More welding cart bead shots

Braces that hold the corners of the welder

Welder, water-cooler, tank and cables installed

This cart was the first thing that I built after I purchased this welder, its been great ever since.

I would like to maybe put larger wheels on it, maybe cap a few of the hose reel lower tube ends, so they can be used as temp storage for fillers.

I also would like to add spots for my (4) 36" sealed rod guard storage tubes.

Maybe around the tank, or diag. on the sides to make room for a 2nd tank.

Water jet cut "dkGoodrich" tags I had made out of stainless and alum.

I put these on any time consuming project

-